I. INTRODUCTION

Automation, system of manufacture designed to extend the capacity of machines to perform certain tasks formerly done by humans, and to control sequences of operations without human intervention. The term automation has also been used to describe nonmanufacturing systems in which programmed or automatic devices can operate independently or nearly independently of human control. In the fields of communications, aviation, and astronautics, for example, such devices as automatic telephone switching equipment, automatic pilots, and automated guidance and control systems are used to perform various operations much faster or better than could be accomplished by humans.

II. ELEMENTS OF AUTOMATION

Automated manufacture arose out of the intimate relationship of such economic forces and technical innovations as the division of labor, power transfer and the mechanization of the factory, and the development of transfer machines and feedback systems as explained below.

The division of labor (that is, the reduction of a manufacturing or service process into its smallest independent steps) developed in the latter half of the 18th century and was first discussed by the Scottish economist Adam Smith in his book An Inquiry into the Nature and Causes of the Wealth of Nations (1776). In manufacturing, the division of labor results in increased production and a reduction in the level of skills required of workers.

Mechanization was the next step necessary in the development of automation. The simplification of work made possible by the division of labor also made it possible to design and build machines that duplicated the motions of the worker. As the technology of power transfer evolved, these specialized machines were motorized and their production efficiency was improved. The development of power technology also gave rise to the factory system of production, because all workers and machines had to be located near the power source.

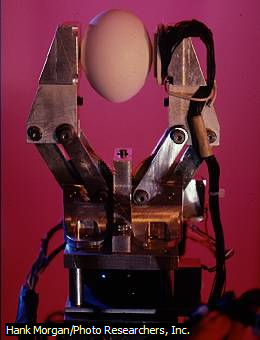

The transfer machine is a device used to move a workpiece from one specialized machine tool (see Machine Tools) to another, in such a manner as to properly position the workpiece for the next machining operation. Industrial robots (see Robot), originally designed only to perform simple tasks in environments dangerous to human workers, are now extremely dexterous and are being used to transfer, manipulate, and index (that is, to position) both light and heavy workpieces, thus performing all the functions of a transfer machine. In actual practice, a number of separate machines are integrated into what may be thought of as one large machine.

In the 1920s the auto industry combined these concepts into an integrated system of production. The goal of this assembly-line system was to make automobiles available to people who previously could not afford them. This method of production was adopted by most automobile manufacturers and rapidly became known as Detroit automation. Despite more recent advances, it is this system of production that most people think of as automation.

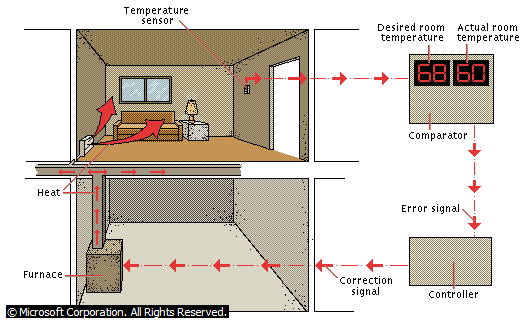

Essential to all automatic-control mechanisms is the feedback principle, which enables a designer to endow a machine with the capacity for self-correction. A feedback loop is a mechanical, pneumatic, or electronic device that senses or measures a physical quantity such as position, temperature, size, or speed, compares it with a preestablished standard, and takes whatever preprogrammed action is necessary to maintain the measured quantity within the limits of the acceptable standard.

The feedback principle has been used for centuries. An outstanding early example is the flyball governor, invented in 1788 by the Scottish engineer James Watt to control the speed of the steam engine. In this device a pair of weighted balls is suspended from arms attached to a spindle, which is connected by gears to the output shaft of the engine. At the top of the spindle the arms are linked by a lever with a valve that regulates the steam input. As the engine speeds up beyond the desired rate, causing the spindle to rotate faster, the flyballs are driven upward by centrifugal force. The action of the flyballs partly closes the input valve, reducing the amount of steam delivered to the engine. The common household thermostat is another example of a feedback device.

In manufacturing and production, feedback loops require that acceptable limits or tolerances be established for the process to be performed; that these physical characteristics be measured and compared with the set of limits; and, finally, that the feedback system be capable of correcting the process so that the measured items comply with the standard. Through feedback devices, machines can start, stop, speed up, slow down, count, inspect, test, compare, and measure. These operations are commonly applied to a wide variety of production operations that can include milling, boring, bottling, and refining.

IV. COMPUTER USE

The advent of the computer has greatly facilitated the use of feedback loops in manufacturing processes. Computers and feedback loops have promoted the development of numerically controlled machines (the motions of which are controlled by punched paper or magnetic tapes) and machining centers (machine tools that can perform several different machining operations).

More recently, the introduction of microprocessors and computer combinations have made possible the development of computer-aided design and computer-aided manufacture (CAD and CAM) technology. When using these systems a designer draws a part and indicates its dimensions with the aid of a special light pen on a televisionlike cathode-ray tube computer display screen. After the sketch has been completed to the satisfaction of the designer, the computer automatically generates a magnetic or punched tape that directs a machining center in machining the part.

Another development that has further increased the use of automation is that of flexible manufacturing systems (FMS). FMS extends automation to companies in which small production runs do not make full automation economically feasible. A computer is used to monitor and govern the entire operation of the factory, from scheduling each step of production to keeping track of parts inventories and tool use.

Automation has also had an influence on areas of the economy other than manufacturing. Small computers are used in systems called word processors, which are rapidly becoming a standard part of the modern office. This technology combines a small computer with a cathode-ray display screen, a typewriter keyboard, and a printer. It is used to edit texts, to type form letters tailored to the recipient, and to manipulate mailing lists and other data. The system is capable of performing many other tasks that increase office productivity.

V. AUTOMATION IN INDUSTRY

Many industries are highly automated or use automation technology in some part of their operation. In communications and especially in the telephone industry, dialing, transmission, and billing are all done automatically. Railroads too are controlled by automatic signaling devices, which have sensors that detect cars passing a particular point. In this way the movement and location of trains can be monitored.

Not all industries require the same degree of automation. Agriculture, sales, and some service industries are difficult to automate. The agriculture industry may become more mechanized, especially in the processing and packaging of foods; however, in many service industries such as supermarkets, for example, a checkout counter may be automated and the shelves or supply bins must still be stocked by hand. Similarly, doctors may consult a computer to assist in diagnosis, but they must make the final decision and prescribe therapy.

The concept of automation is evolving rapidly, partly because the applications of automation techniques vary both within a plant or industry and also between industries. The oil and chemical industries, for example, have developed the continuous-flow method of production, owing to the nature of the raw materials used. In a refinery, crude oil enters at one point and flows continuously through pipes in cracking, distillation, and reaction devices as it is being processed into such products as gasoline and fuel oil. An array of automatic-control devices governed by microprocessors and coordinated by a central computer is used to control valves, heaters, and other equipment, thereby regulating both the flow and reaction rates.

In the steel, beverage, and canned food industries, on the other hand, some of the products are produced in batches. For example, a steel furnace is charged (loaded with the ingredients), brought up to heat, and a batch of steel ingots produced. In this phase very little automation is evident. These ingots, however, may then be processed automatically into sheet or structural shapes by being squeezed through a series of rollers until the desired shape is achieved. See Iron and Steel Manufacture.

The automobile and other consumer product industries use the mass production techniques of step-by-step manufacture and assembly. This technique approximates the continuous-flow concept but involves transfer machines; thus, from the point of view of the auto industry, transfer machines are essential to the definition of automation. See Automobile Industry.

Each of these industries uses automated machines in all or part of its manufacturing processes. As a result, each industry has a concept of automation that fits its particular production needs. More examples can be found in almost every phase of commerce. The widespread use of automation and its influence on daily life provides the basis for the concern expressed by many about the influence of automation on society and the individual.

VI. AUTOMATION AND SOCIETY

Automation has made a major contribution toward increases in both free time and real wages enjoyed by most workers in industrialized nations. Automation has greatly increased production and lowered costs, thereby making automobiles, refrigerators, televisions, telephones, and other goods available to more people. It has allowed production and wages to increase, and at the same time the work week has decreased in most Western countries from 60 to 40 hours.

- Employment

Not all the results of automation have been positive, however. Some commentators argue that automation has caused overproduction and waste, that it has created alienation among workers, and that it generates unemployment. Of these issues, the relationship between automation and unemployment has received the most attention. Employers and some economists argue that automation has little if any effect on unemployment—that workers are displaced rather than dismissed and are usually employed in another position within the same company or in the same position at another company that has not automated.

Some claim that automation generates more jobs than it displaces. They point out that although some laborers may become unemployed, the industry producing the automated machinery generates more jobs than were eliminated. The computer industry is often cited to illustrate this claim. Business executives would agree that although the computer has replaced many workers, the industry itself has generated more jobs in the manufacturing, sales, and maintenance of computers than the device has eliminated.

On the other hand, some labor leaders and economists argue that automation causes unemployment and, if left unchecked, will breed a vast army of unemployed that could disrupt the entire economy. They contend that growth in government-generated jobs and in service industries has absorbed those who became unemployed due to automation, and that as soon as these areas become saturated or the programs reduced, the true relationship between automation and unemployment will become known.

- Automation and the Individual

The effect of automation on the individual has been more drastic. The worker is either displaced or unemployed. Workers who remain must operate or maintain technologically advanced machines, and they may also be required to monitor more of the plant operation and to make on-the-spot decisions. Thus, the education and experience levels of these workers are considerably above those of the workers who were displaced.

Many researchers have described the effect that Detroit automation has on the individual worker as one of alienation. Excessive absenteeism, poor workmanship, and problems of alcoholism, drug addiction, and sabotage of the production lines are well-documented symptoms of this alienation. Many studies have been made since the 1930s, and all conclude that much of the alienation is due to the workers’ feelings of being controlled by the machine (because workers must keep pace with the assembly line), boredom caused by repetitious work, and the unchallenging nature of work that requires only a minimum of skill.

The number of workers in more automated industries, especially those using continuous flow processes, tends to be small, and the capital investment in equipment per worker is high. The most dramatic difference between these industries and those using Detroit automation is the reduction in the number of semiskilled workers. It would appear then that automation has little use for unskilled or semiskilled workers, their skills being the most easily replaced by automated devices. The labor force needed in an automated plant consists primarily of such skilled workers as maintenance engineers, electricians, and toolmakers, all of whom are necessary to keep the automated machinery in good operating order.

____________________________________________

Sources:

Microsoft Encarta

____________________________________________